| S No | Name of the Lab | Equipment Name | Specification | Description | Testing Capabilities | Staff In-charge |

|---|---|---|---|---|---|---|

| 1 | Advanced Materials Lab | Salt Spray Analyzer

| 1. Compliance Standards: ASTM B117, ISO 9227, JIS Z 2371 2. Chamber Volume: Typically ranges from 250 to 2000 liters 3. Temperature Range: Ambient to 55°C (±1°C accuracy) 4. Spray Method: Atomized fog dispersion | The Salt Spray Analyzer is utilized for accelerated corrosion testing of materials and coatings. It simulates harsh, saline environmental conditions to evaluate corrosion resistance and durability of materials, coatings, metals, alloys, and composites. | 1. Valuation of corrosion resistance for metals, alloys, and coated surfaces 2. Assessment of protective coatings (paint, plating, anodizing, galvanization) 3. Determining pitting and crevice corrosion behavior 4. Performance verification under standardized corrosion conditions | Dr. P. Ram Kumar Contact No. – 8754603464, Email:prrchem@tce.edu |

| 2 | Advanced Materials Lab | Hot Air Oven  | 1. Temperature Range: Ambient +5°C to 300°C 2. Controller: Digital PID controller with timer (0–999 minutes) 3. Heating Element: Nichrome wire/ceramic-coated heating elements | The hot air oven is extensively used for thermal treatment, drying, and annealing of nanomaterials. | 1. Post-synthesis annealing to improve crystallinity and phase purity 2. Stabilization of nanoparticle coatings on substrates 3. It is a key tool for preparing oxide nanoparticles, polymer composites, and hybrid nanomaterials before further characterization | Dr. P. Ram Kumar |

| 3 | Advanced Materials Lab | UV Chamber  | 1. UVA-340 fluorescent lamps 2. UVA: 340 nm ±10 nm; UVB: 313 nm ±10 nm 3. 48 test samples or more, depending on the mode | Simulates the damaging effects of sunlight, dew, and rain using fluorescent UV lamps and controlled condensation cycles. Accelerates aging to test material durability under outdoor-like conditions. | 1. UV degradation analysis 2. Color fading and yellowing 3.Mechanical integrity post-UV exposure 4. Surface cracking or embrittlement detection | Dr. P. Ram Kumar |

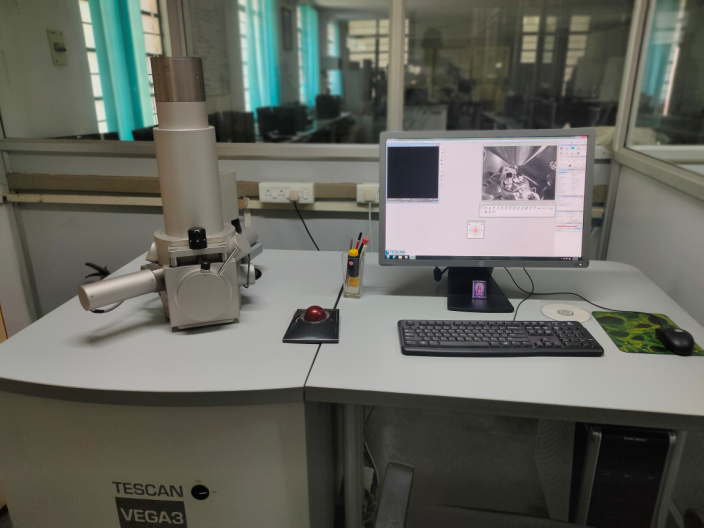

| 4 | Advanced Materials Lab | Scanning Electron Microscopy

| TESCAN-VEGA-3-Scanning Electron Microscope - Materials technology lab Department of Chemistry. | A scanning electron microscope (SEM) is a type of electron microscope that produces images of solid samples by scanning the surface with a focused beam of electrons. | 1. SEM is used to examine the surface of a sample at a higher resolution 2. Evaluation of particle size, shape, porosity, grain size, and grain boundary | Dr M Velayudham Contact No. – 9842378423, Email: mvchem@tce.edu |