Centre of Excellence in Hydrogen Energy Research-Facilities

| S No | Name of the Lab | Equipment Name | Specification | Description | Testing Capabilities | Staff In-charge |

|---|---|---|---|---|---|---|

| 1 | Centre of Excellence in Hydrogen Energy Research | Pyrolysis unit  | 1. Converts bio-waste and plastics into fuel. 2. Operates at 600–800°C. 3. Uses electric heating. 4. Batch or fixed-bed type reactor. 5. Includes a condenser to collect liquid fuel. 6. Produces oil, gas, and solid char | The pyrolysis unit breaks down waste materials using heat. It works without oxygen. Plastic and organic waste are heated to high temperatures. The vapors are condensed into liquid fuel. Solid char and gas are also collected. This process helps recycle waste into energy | 1. Measures fuel yield from waste. 2. Tests oil composition using GC-MS or FTIR. 3. Evaluates plastic-to-fuel conversion rate. 4. Determines optimal pyrolysis temperature. 5. Analyzes residue for quality and ash content. 6. Supports pilot and scale-up testing | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 2 | Centre of Excellence in Hydrogen Energy Research | Hot Air Oven  | 1. Temperature Range: Ambient +5°C to 300°C. 2. Controller: Digital PID controller with timer (0–999 minutes) 3. Heating Element: Nichrome wire/ceramic-coated heating elements | The hot air oven is extensively used for thermal treatment, drying, and annealing of nanomaterials. | 1. Post-synthesis annealing to improve crystallinity and phase purity. 2. Stabilization of nanoparticle coatings on substrates. 3. It is a key tool for preparing oxide nanoparticles, polymer composites, and hybrid nanomaterials before further characterization | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 3 | Centre of Excellence in Hydrogen Energy Research | UV Chamber  | 1. UVA-340 fluorescent lamps 2. UVA: 340 nm ±10 nm; UVB: 313 nm ±10 nm 3. 48 test samples or more, depending on the mode | Simulates the damaging effects of sunlight, dew, and rain using fluorescent UV lamps and controlled condensation cycles. Accelerates aging to test material durability under outdoor-like conditions | 1. UV degradation analysis 2. Color fading and yellowing 3. Mechanical integrity post-UV exposure 4. Surface cracking or embrittlement detection | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

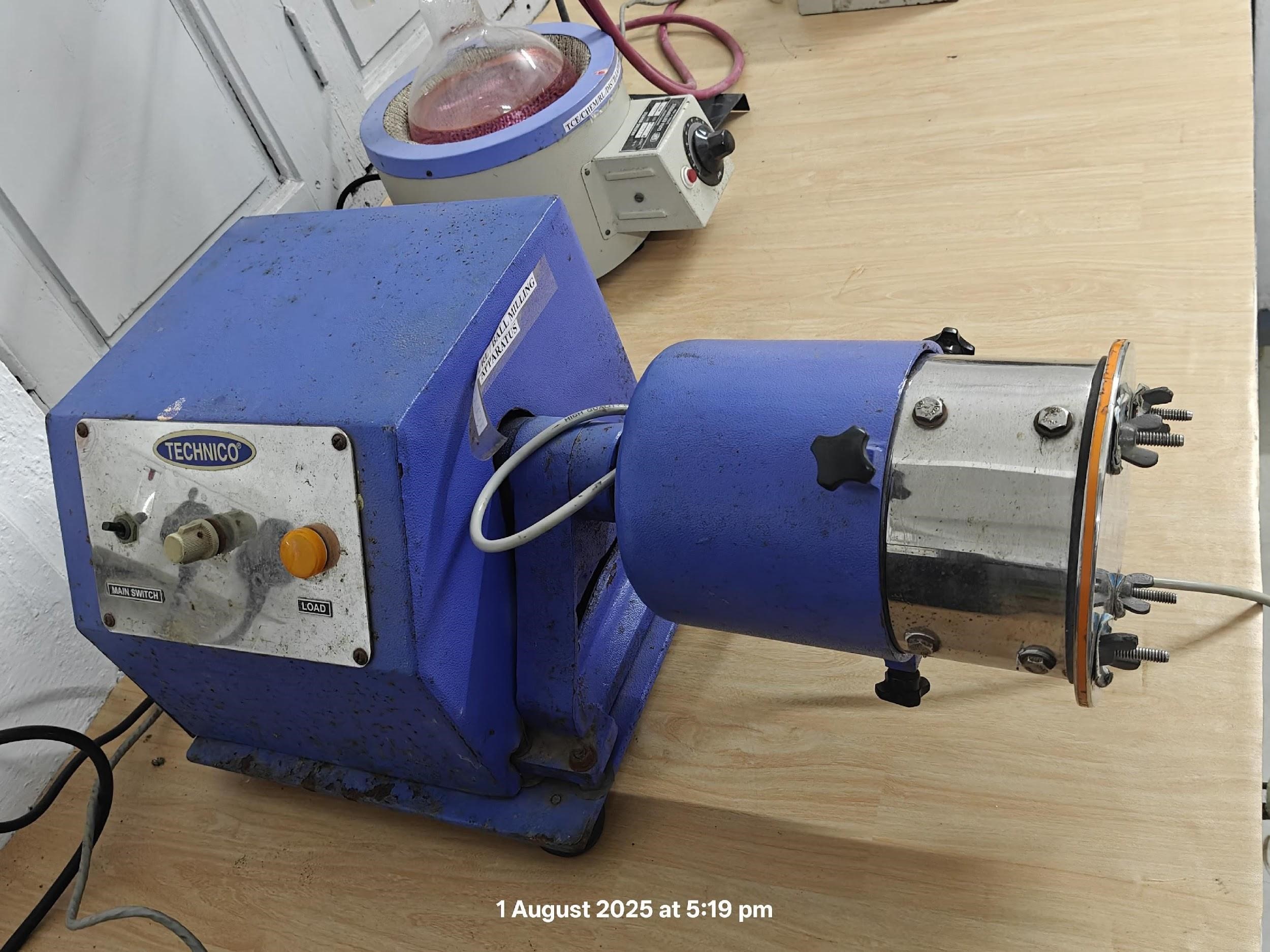

| 4 | Centre of Excellence in Hydrogen Energy Research | Ball milling unit  | 1. For grinding and mixing powders. 2. Speed: 100–600 rpm. 3. Jar: 250 ml–1 L. 4. Uses steel or carbide balls. 5. Dry or wet mode 6. Timer-controlled. 7. Can run in inert gas | A ball mill grinds materials by impact and friction. It mixes powders uniformly. Used in nanomaterial and composite preparation. | 1. Particle size reduction 2. Powder homogenization 3. Nano-alloying and blending 4. Sample prep for XRD, SEM, FTIR. | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 5 | Centre of Excellence in Hydrogen Energy Research | Domestic microwave oven for thermal treatments  | 1. Uses microwave energy for heating 2. Power: 700–1200 W 3. Temperature: Up to 300°C 4. Digital timer and temp control 5. Chamber: ceramic or quartz base 6. Safety interlock and shielding | It is used for fast and uniform heating of materials. Ideal for drying, curing, and thermal activation Saves energy and reduces process time. | 1. Thermal treatment of nanomaterials

| Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 6 | Centre of Excellence in Hydrogen Energy Research | Solar simulator  | 1. Simulates sunlight for lab-scale testing 2. Light intensity: 1 Sun (1000 W/m²) 3. Spectrum: AM 1.5 Global standard 4. Uniform illumination over 100×100 mm area 5. Equipped with Xenon or LED light source 6. Power adjustable, stable output 7. Integrated cooling system | The solar simulator mimics natural sunlight for testing solar devices. It provides controlled, repeatable light conditions. Suitable for PV, DSSC, and photocatalysis studies. | 1. IV curve measurement of solar cells 2. Light soaking and stability tests 3. Quantum efficiency and power output 4. Photocatalyst and photoelectrode evaluation | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 7 | Centre of Excellence in Hydrogen Energy Research | DC power supply units  | 1. Output: 0–30 V / 0–5 A (typical) 2. Dual/Triple channel output 3. Digital voltage and current display 4. Fine and coarse adjustment knobs 5. Overload and short-circuit protection 6. Regulated and stable output | DC power supplies deliver stable voltage and current to lab devices. Commonly used for electrochemical cells, sensors, and circuit testing. | 1. Powering electrochemical setups 2. Charging/discharging battery cells 3. Supplying current to sensors/devices 4. Evaluating circuit response under load | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 8 | Centre of Excellence in Hydrogen Energy Research | Spin coater  | 1. Speed: 500–8000 rpm (programmable) 2. Timer: 1–999 seconds 3. Substrate size: up to 4 inches 4. Acceleration control enabled 5. Vacuum chuck for firm holding 6. Transparent lid for process viewing | The spin coater deposits uniform thin films on flat substrates. Used for coating polymers, oxides, and photoresists in research labs. | 1. Thin film deposition for DSSC and sensors. 2. Coating control via speed and time. 3. Layer uniformity and repeatability tests. 4. Substrate compatibility and material adhesion studies | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464, Email: prrchem@tce.edu |

| 9 | Centre of Excellence in Hydrogen Energy Research | Andslite Solar Panel  | 1. Type: Polycrystalline or Monocrystalline 2. Power Output: 10W–40W (varies by model) 3. Voltage: 12V DC 4. Efficiency: ~15–18% 5. Rugged, weather-resistant frame 6. Prewired for plug-and-play use | Andslite solar panels are compact and efficient. Used for small solar experiments, battery charging, and off-grid applications. | 1. Solar energy harvesting studies 2. Powering DC devices and sensors 3. Performance under varied sunlight 4. Integration with solar charge controllers | Coordinators: Dr. M. Kottaisamy Dr. P. Ram Kumar Contact No. – 8754603464 Email: prrchem@tce.edu |